Our handcrafted glass tables are gaining more and more followers among our interior design and designer clients. The reason is, in addition to its obvious beauty, the many possibilities that handmade glass offers when it comes to personalizing its design and adapting it to the needs of each space. Today we are going to tell you what lies behind these pieces that we see more and more every day in top-level restaurants, hotels and commercial establishments: artisan hands that play with textures, tones and colours to create these unique pieces.

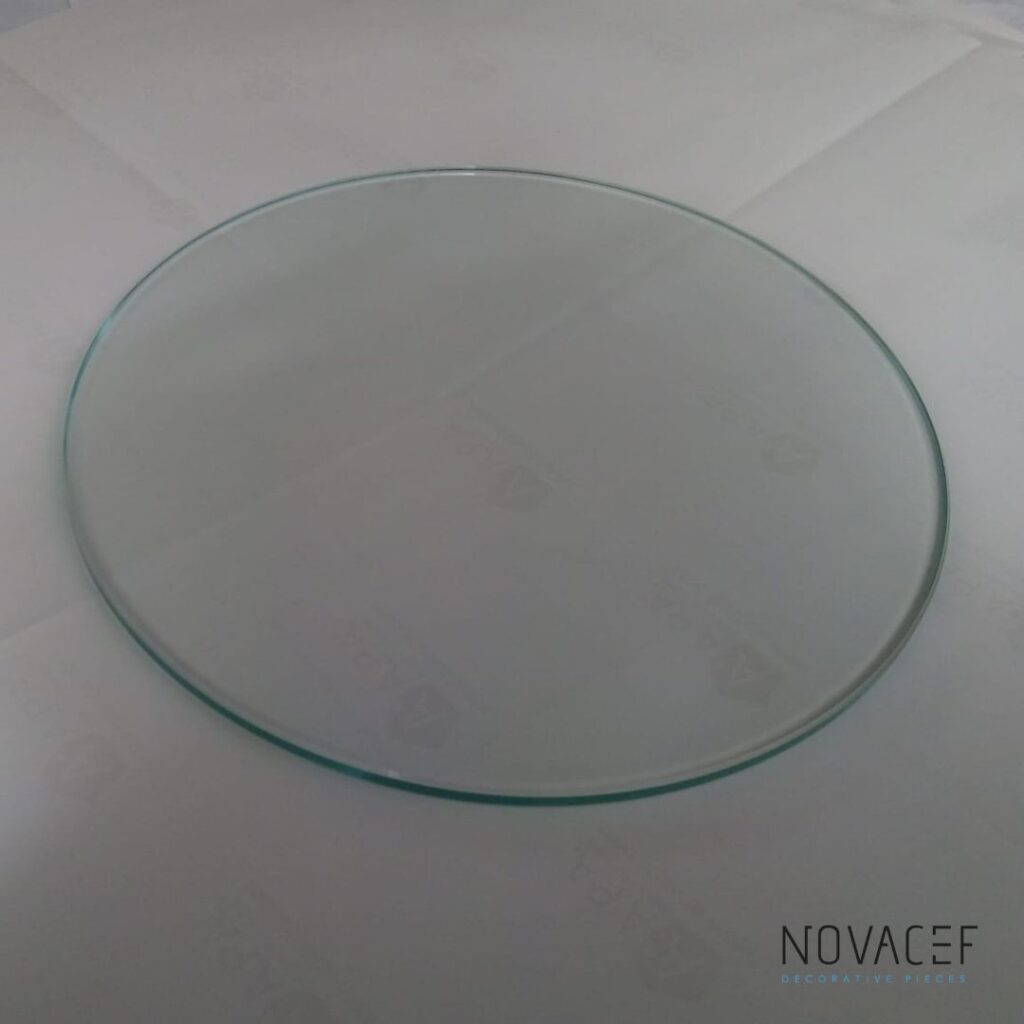

The artisanal process begins first with the cutting of the piece, in this case 8 millimeters thick.

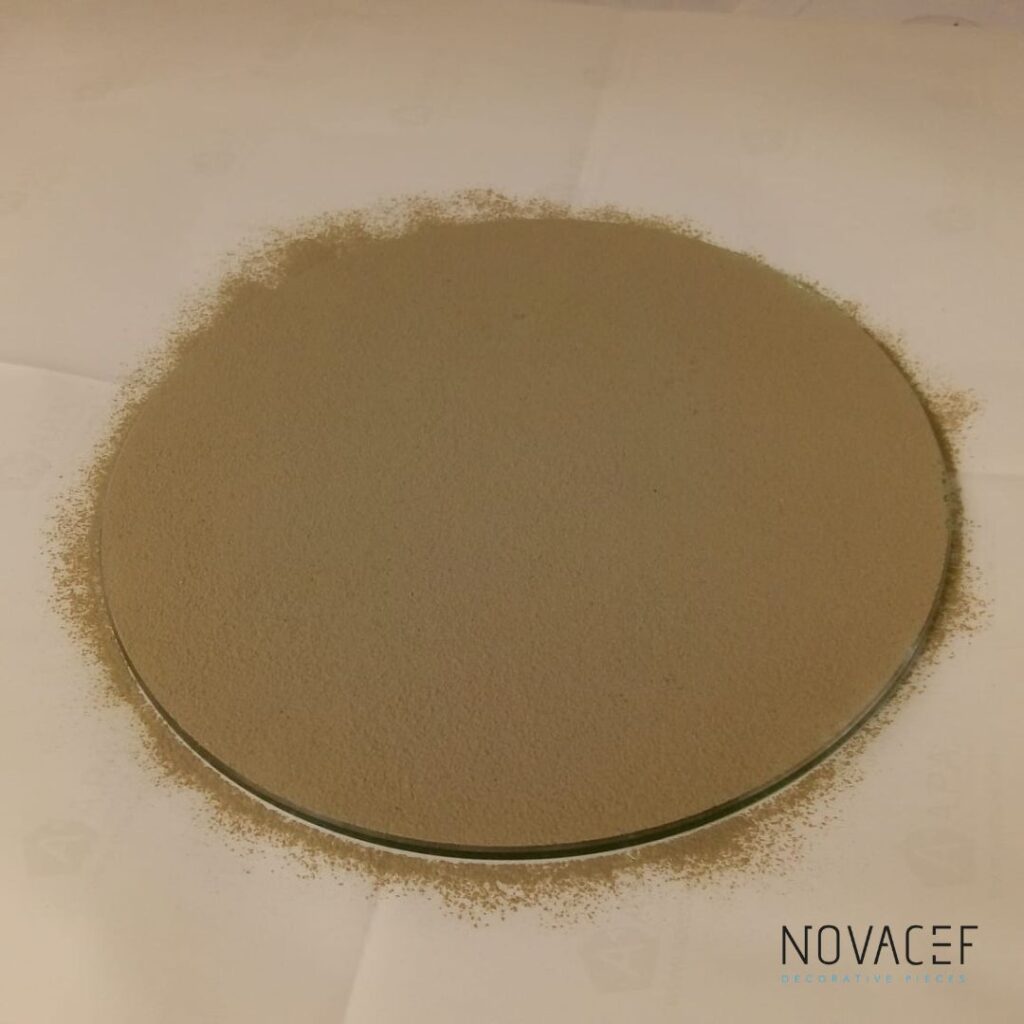

In the second image you can see how the craftsman distributes the coloured glass powder, in this case grain 1, over the entire surface.

In the third image you can see the next step in the creation process, which is how the surface looks when the comb-type mold is passed over the crystal powder, drawing the shape that the client desires.

The piece is then placed in the oven at a temperature of approximately 830º to melt.

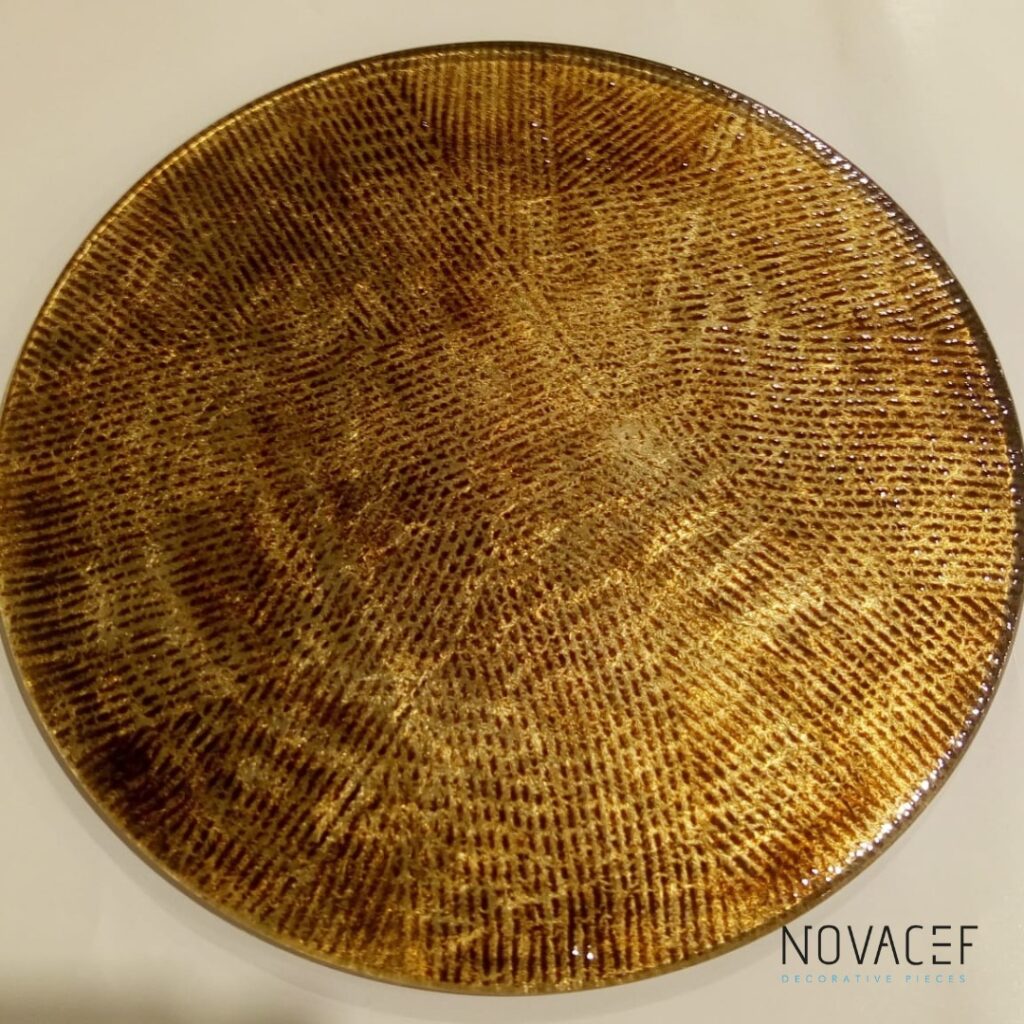

Once melted, gold leaf is placed on the surface to complete the process with special paint for glass.

In this way, we will have our finished piece, with each of the steps being customizable for a different finish in color, texture, … the possibilities are endless and that is precisely what gives these pieces a versatility that is making many designers include them in their projects, especially those related to first-class hotels and restaurants, but also in homes and commercial establishments.

Now all that remains is to add the support to our clients’ taste to complete the piece, as we show you below with a table made with our ubud model and black iron support. A series we created for a very stylish restaurant.